Write FANUC design and style G-codes specifically into your Editor or pick out instructions off the [Select] menu and write your tool path program in conversational manner which include precisely what is written while in the Editor box. You can even mix between discussion commands and G-codes in a similar program.

Semi-automatic CNC lathes need somewhat more get the job done from the machine operator Whilst thoroughly automatic centres can easily do all the things from mounting the workpieces to shifting the tools.

The mattress is simply a foundation plate that rests about the table, supporting other machine parts. The carriage operates about the bed which happens to be heat-dealt with to withstand the machining outcomes.

Orientation: The spindle is positioned vertically, with the workpiece connected to some horizontal chuck.

By being familiar with the nuances of CNC lathe operation, lifespan, as well as variances from conventional lathes, businesses and operators can make educated selections that increase productivity and manage high-quality.

Applying common Home windows features to edit your method you could then lock the Editor Screen to stop accidental editing, and if you have to insert a line in the middle of a method, just click [ReNum] to re-variety your tool route record.

Following comes the machine setup. This is when the machine operator’s function results in being evident. Whilst modern day CNC lathes do almost all of the perform quickly, the operator nevertheless performs a significant element.

You'll be able to then add Spindle ON, feed instructions, and press Check out operate The brand new program as necessary. This is an excellent attribute that may help you study to produce a plan because of the actions you make to the machine without always crafting out a whole application initially.

Identical in form to CNC mills, CNC drills utilize a spindle and drill but instead of forming a part, as an alternative only Minimize holes. These holes might be exactly made for dimension, diameter, and depth.

Locating the best inexpensive CNC machine could be a problem. You need something which received’t cripple your price range but will provide the versatility and power you must extend your online business.

Application it to drill straight by way of for your whole depth, make use of a high-speed pecking cycle, or deep hole pecking cycle. You may program the cut-in depth and return point for the controlled peck drill application To optimize chip clearance.

Also, the enclosures appreciably lessen the chance throughout machining, as the staff are not really exposed to any moving components, controlling just about anything vital from a display screen.

The time Visit this page period turning refers to making parts by slicing operations on the external surface. The opposite of turning is dull, whereby lathe machines are employed for producing hollow parts, as an example.

3D Modeling Software: Utilized for developing complex 3D models that can be translated into machining operations. Rhino and Blender are suited to additional artistic or intricate patterns.

Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Hailie Jade Scott Mathers Then & Now!

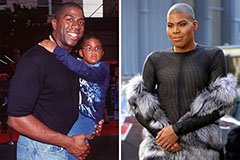

Hailie Jade Scott Mathers Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!